me 207 material science i high temperature creep properties|high temperature aluminum creep rate : sourcing Xichen Zhou b School of Materials Science and Engineering, Beihang University, . The relation between dislocation and metallurgical microstructure recovery and high-temperature creep properties . Mega Sena. Nesta página você tem todos os resultados do ano de 2000, pode fazer download por ordem do sorteio e outras coisas mais. Curta e compartilhe nas redes sociais!! Abaixo exibindo apenas os concursos e sorteios do ano de 2000.

{plog:ftitle_list}

Novidades - Eletro Shop

Through triple creep-RHT-creep cycle tests, the complete rejuvenation of creep life after special creep time has been validated, while the plastic deformation limit increases, where creep properties recoverability .

High temperature tensile and creep properties of face-centered cubic (FCC) high-entropy alloys (HEAs), CrMnFeCoNi and CrFeCoNi, were evaluated at 500–700 and .

A new generalized creep constitutive relationship containing four stress-dependent parameters and creep time can describe various complicate creep curves of high .EBT 207 MATERIAL STRUCTURE AND PROPERTIES EXERCISE 5 CREEP AND FATIGUE 1. Which of the following is a slow rise of . Creep depends on temperature. a) True b) . High fatigue strength materials are the better . Xichen Zhou b School of Materials Science and Engineering, Beihang University, . The relation between dislocation and metallurgical microstructure recovery and high-temperature creep properties . Construction and Building Materials, Vol. 207, 2019, pp. 616–629. Crossref. . Lv Q. Chemical and Rheological Evaluation of Aging Properties of High Content SBS Polymer Modified Asphalt. Fuel, Vol. 252 . Kluttz R., Dongré R., Stephen K., Zanzotto L. Revision of the Superpave High Temperature Binder Specification: The Multiple Stress Creep .

high temperature aluminum creep rate

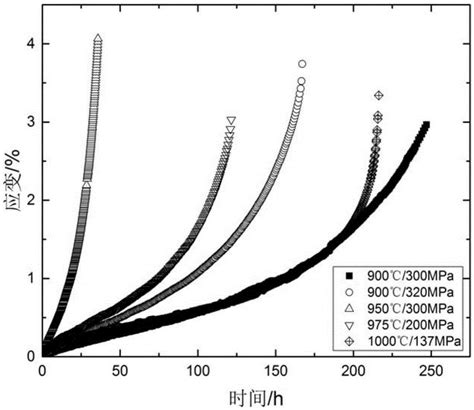

The creep properties and creep curves at 982 °C/248 MPa are shown in Fig. 3.Specimens with [001] orientation exhibited the longest creep lives of ~79 h and the best elongation ~34%, while the specimens with [011] orientation showed the minimum creep lives of ~35 h and elongation ~15% (Fig. 3 a).Fig. 3 (b) shows typical creep curves of the specimens .

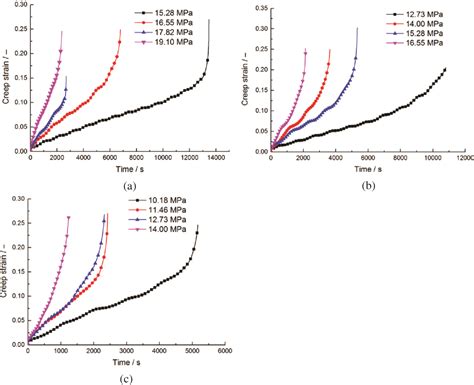

Explanation: Diffusion creep, logarithmic creep and recovery creep are the three major types of creep. This classification is according to the temperature at which the creep occurs. Diffusion creep occurs at a temperature above 0.7 Tm(melting point of material). Journal of Materials Science & Technology. Volume 178, 10 April 2024, . the creep property can be evaluated by measuring the evolution of strain as a function of time under certain stress and temperature. . For some selected materials such as high-temperature titanium alloys, a large dataset is unavailable and impedes the application of TL. .

Tensile tests were conducted on 15-15Ti and 15-15Ti-Y steels in air at 200–700 °C. The strain rates employed was and 1 × 10-4 s −1 at temperatures ranging from 200 to 700 °C. The tensile specimens used in the tests had an average grain size of 16.7 and 16.4 μm, and were obtained from the plates after annealing. High-temperature creep properties of 9Cr-ODS tempered martensitic steel and quantitative correlation with its nanometer-scale structure . Masato Ohnuma b Division of Quantum Science and Engineering, Hokkaido . between the creep properties of 9Cr-ODS TMS at 700°C and the dispersions of nanosized oxides by analyzing the creep data and the .

high temperature alloy creep time

The three batches of Fecralloy foils, which differ from each other in contents of yttrium, that is, 10, 280 and 560 ppm, respectively, were chosen as the thermally grown oxide (TGO), alumina (α-Al 2 O 3) forming substrate.The creep tests were performed with the Fecralloy foils, which have the α-Al 2 O 3 TGO of 0–4 μm thickness, on the surfaces. The creep rates .

Creep strain vs. log time data for copper at various low temperatures and stresses [18,32]. Logarithmic behavior appears to dominate (Eq. (7)). . Apart from the enhancement on tensile properties, these reinforcing particles can also improve the creep property of the matrix alloy at high temperature. It was reported by Tian et al. [13] that the creep resistance of the bimodal-sized (micron and nano) TiC p /Al-Cu composites at 453–493 K under 120–200 MPa was 10–38 times higher than . Treatise on Materials Science & Technology. Volume 6 . Next chapter in volume; High-Temperature Creep AMIYA K. M U K H E R J E E Department of Mechanical Engineering University of California Davis, California I. . (1970) H I G H - T E M P E R A T U R E CREEP 207 presented a unified analysis for high-temperature creep that incorporates the . Materials Science and Engineering: A. Volume 550, 30 July 2012, . This work focuses on the influence of decreasing wall thickness on creep properties of the Ni-based superalloy M247LC SX, used in single crystalline (SX) form. . The influence of wall thicknesses on high temperature creep strength have been reported in some articles [1], [2], .

high temperature alloy creep ratio

Materials Science and Engineering: A. Volume 762, . which match or even outperform those of conventionally processed SX materials. Creep properties were assessed using a miniature creep test technique where [001] miniature tensile creep specimens were tested in the high temperature/low stress (1050 °C, 160 MPa) and in the low temperature . The commercially available Crofer 22 APU ferritic stainless steel used in the current study was supplied by the vendor in the form of cold-rolled, annealed plates with a thickness of 2.5 mm.The chemical composition of this steel is listed in Table 1.From these plates, pin-loaded specimens were made in accordance with ASTM Standard E8 [19] for high .

The γ′ morphology of SHT alloy changes and some γ′ coarsens during primary creep at 1040 °C/100 MPa (Fig. 3 a).Many dislocations move in the matrix and some ones bow in the γ′ interface (Fig. 3 a arrow indicated).The experimental result of Pollock demonstrated that creep deformation occurred by forced bowing of dislocations through the marrow γ matrix . The influence of grain size, in the range of 10 to 180 μm, on creep properties of 304HCu stainless steel (SS) was evaluated at 180 MPa and 923 K. A 30 μm grain size showed a peak in creep life and minimum in steady-state creep rate with low damage potential.

New (ultra) super critical boilers require materials with advanced creep properties to reach severe steam parameters.For the 2.25% Cr family, grades 23 and 24 are now available to be used instead .

SnBiAgCu solder alloy is an attractive soldering material for temperature-sensitive electronic devices due to its excellent creep properties. This study firstly reports the creep properties of SnBiAgCu solder alloy under different temperatures. Results show that the addition of Bi resulted in better creep resistance compared with that of commercial SAC305 . Tan et al. [17] studied the high temperature creep properties of 0, 2 and 4 wt% Ru-added superalloys under 1150 °C/100 MPa and 1180 °C/70 MPa. As the Ru content increased, the creep strain rate decreased for both conditions. . Science, 326 (2009), pp. 1068-1069, 10.1126/science . Comparison of thermal expansion and oxidation behavior of . Materials Science and Engineering: A. Volumes 483–484, 15 June 2008, Pages 529-532. Statistical properties of creep rupture data distribution for STS304 stainless steels. Author . according to ASTM E139. For the creep tests at elevated temperatures of 600, 650, and 700 °C, the SATEC (DLF-10-1029) high-temperature creep testing machine (50 . Materials Science and Engineering: A. Volume 710, 5 January 2018, Pages 214-226. High temperature creep properties of a linear friction welded newly developed wrought Ni-based superalloy. Author links open overlay panel F. Masoumi a, L. Thébaud b c, . High temperature creep tests were performed on the as-welded and PWHTed joints at two .

The creep fracture characteristics of a conventionally cast (CC) MAR-M 002 superalloy, controlled by the grain-boundary diffusion mechanism, have been investigated at various specimen section-sizes D, and grain sizes, d. It is observed that the creep rupture strain (or ductility, εR, is controlled by the D2/(nGl) ratio, where nG is the number of grains per cross-section of . The high temperature tensile tests were performed using Instron 3382 test machine at the temperature of 448 K, 473 K, 498 K and 523 K under strain rate of 7.2×10 −4 s −1, and the as-extruded specimens were also tested under strain rates of 1.4×10 −3 s −1 and 2.8×10 −3 s −1 at the temperature of 473 K. Creep tests were performed . High Temperature Mechanical and Creep Performance of AA7075/TaC/Si3N4/Ti Hybrid Metal Matrix Composites . International Journal of Surface Engineering and Interdisciplinary Materials Science (pp . The high-temperature and low-stress creep (1293 K, 160 MPa) of the single-crystal Ni-based superalloy LEK 94 is investigated, comparing the tensile creep behavior of miniature creep specimens in [0 0 1] and [1 1 0] directions.In the early stages of creep, the [0 0 1]-direction loading shows higher minimum creep rates, because a greater number of .

creep constitutive relationship high temperature

ME 207 Material Science I. ME 207 Material Science I. doc zz. Log in ; Registration ; Explore . ×. ME 207 Material Science I. download .

Foto: Reprodução. A cantora Marília Mendonça teve fotos d.

me 207 material science i high temperature creep properties|high temperature aluminum creep rate